|

| January 14, 2020 | Volume 16 Issue 02 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

One-part epoxy changes from red to clear under UV

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Learn more.

SPIROL Press-N-Lok™ Pin for plastic housings

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

Learn more about the new Press-N-Lok™ Pin.

Why hybrid bearings are becoming the new industry standard

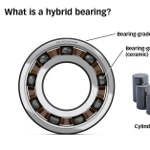

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

Read the SKF technical article.

3M and Ansys train engineers on simulating adhesives

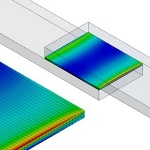

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Read this informative Ansys blog.

New FATH T-slotted rail components in black from AutomationDirect

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Learn more.

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

New interactive digital catalog from EXAIR

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

Check out EXAIR's online catalog.

5 cost-saving design tips for CNC machining

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

View the video.

What can you secure with a retaining ring? 20 examples

From the watch dial on your wrist to a wind turbine, no application is too small or too big for a Smalley retaining ring to secure. Light to heavy-duty loads? Carbon steel to exotic materials? No problem. See how retaining rings are used in slip clutches, bike locks, hip replacements, and even the Louvre Pyramid.

From the watch dial on your wrist to a wind turbine, no application is too small or too big for a Smalley retaining ring to secure. Light to heavy-duty loads? Carbon steel to exotic materials? No problem. See how retaining rings are used in slip clutches, bike locks, hip replacements, and even the Louvre Pyramid.

See the Smalley design applications.

Load fasteners with integrated RFID

A crane, rope, or chain may be required when something needs lifting -- plus anchoring points on the load. JW Winco offers a wide range of solutions to fasten the load securely, including: lifting eye bolts and rings (with or without rotation), eye rings with ball bearings, threaded lifting pins, shackles, lifting points for welding, and more. Some, such as the GN 581 Safety Swivel Lifting Eye Bolts, even have integrated RFID tags to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

A crane, rope, or chain may be required when something needs lifting -- plus anchoring points on the load. JW Winco offers a wide range of solutions to fasten the load securely, including: lifting eye bolts and rings (with or without rotation), eye rings with ball bearings, threaded lifting pins, shackles, lifting points for welding, and more. Some, such as the GN 581 Safety Swivel Lifting Eye Bolts, even have integrated RFID tags to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

Learn more.

Couplings solve misalignments more precisely with targeted center designs

ALS Couplings from Miki Pulley feature a simplistic, three-piece construction and are available in three different types for more precisely handling parallel, angular, or axial misalignment applications. The key feature of this coupling design is its center element. Each of the three models has a center member that has a unique and durable material and shape. Also called a "spider," the center is designed to address and resolve the type of misalignment targeted. Ideal for unidirectional continuous movement or rapid bidirectional motion.

ALS Couplings from Miki Pulley feature a simplistic, three-piece construction and are available in three different types for more precisely handling parallel, angular, or axial misalignment applications. The key feature of this coupling design is its center element. Each of the three models has a center member that has a unique and durable material and shape. Also called a "spider," the center is designed to address and resolve the type of misalignment targeted. Ideal for unidirectional continuous movement or rapid bidirectional motion.

Learn more.

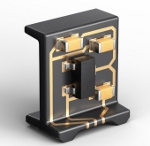

What is 3D-MID? Molded parts with integrated electronics from HARTING

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

View the video.

Army develops cold spray technology to repair Bradley gun mounts

An Army M2 Bradley Fighting Vehicle stages out on a breaching range during a dry run of dismounted breach training conducted on a range in Poland, May 23, 2019. With funding from the Army's Manufacturing Technology Program, a team of scientists and engineers from the U.S. Army CCDC worked together to develop a cold spray process to repair costly turret gun mounts on the Army's M2 Bradley Fighting Vehicle. [Photo Credit: Jeremiah Woods]

By Argie Sarantinos-Perrin, CCDC, Aberdeen Proving Ground, MD

Repairing a 40-ton armored vehicle is a lot harder than having your car fixed at a neighborhood auto repair shop. Tactical armored vehicles require specialized repair procedures, which are very costly. What if repairing routine wear and tear on an Army vehicle was inexpensive and as easy as fixing your car?

With funding from the Army's Manufacturing Technology Program, a team of scientists and engineers from the U.S. Army Combat Capabilities Development Command (CCDC) Army Research Laboratory, Ground Vehicle Systems Center, and the Armaments Center, as well as Bradley Product Manager and Red River Army Depot (RRAD) worked together to develop a cold spray process to repair costly turret gun mounts on the Army's M2 Bradley Fighting Vehicle.

"This project demonstrated the ability to apply new manufacturing technologies to bring components back into service that would otherwise be scrapped during depot maintenance operations," said Gehn Ferguson, CCDC ARL materials engineer.

The project began in 2017 when CCDC ARL visited RRAD to view the inspection process and access the wear on the Bradley turret gun mounts. RRAD, the primary depot responsible for the Bradley vehicle, inspects gun mounts for excessive wear. In subsequent months, CCDC ARL developed and demonstrated a process for repairing the gun mounts using cold spray. Prior to developing the cold spray process, worn gun mounts that were inspected and identified as non-repairable were disposed of.

The 25-mm gun mount supports the gun barrel on the M2 Bradley Fighting Vehicle. When the mount begins to wear unevenly, the barrel becomes less stable. The Army is evaluating if a cold spray process can be used to repair the gun mount. [Photo Credit: U.S. Army]

"Cold spray is an emerging technology that will enable the Army to reclaim worn components that were previously replaced with new parts. This new technology reduces lifecycle cost and improves systems availability," Ferguson said.

While the cost of a new 25-mm gun mount is more than $25,000, a cold spray repair costs approximately $1,000. Additionally, the cold spray process improves readiness by reducing the time that a Bradley is out of service while lessening the burden on the supply chain by reducing the necessity for stockpiling new gun mounts.

Cold spray is a process where micron-sized particles are accelerated in a high-velocity gas stream through a nozzle and subsequently consolidated on a target surface. The accelerated particles impact and bond to the surface, resulting in a buildup of the sprayed material. Both the sprayed particles and the target surface remain solid during the process.

Using the cold spray process, CCDC Army Research Laboratory restored the internal diameter of the gun mount exit throat to its original drawing dimensions, demonstrating the ability to return worn gun mounts back into service. [Photo Credit: U.S. Army]

The Bradley turret gun mount was selected as a candidate for the cold spray repair process because CCDC ARL has extensive experience working with similar steels, and an established process to repair the worn gun mounts didn't exist. CCDC Armaments Center was responsible for designing and engineering the turret, and CCDC ARL developed and demonstrated the cold spray repair procedure. The Tank-Automotive and Armaments Command is reviewing the repair and overhaul instructions currently under development. The team plans to repair four or five gun mounts within the next six months.

While the project initially began as a way to repair gun mounts, the material used in the cold spray process is much more durable, which suggests it could even be used to extend the life of new gun mounts.

Cold spray is also being evaluated for use with other applications, including the ability to repair corrosion on combat vehicle surfaces and possibly to coat the interior of cannon barrels. For example, if the inside of a cannon barrel can be effectively coated with tantalum, which is a very durable material, its service life can be extended.

"As the command develops new weapon systems, there will be more opportunities to leverage the cold spray process to augment or repair components that may otherwise be labeled unusable. We're hoping this new manufacturing technology will lead to more success stories that will validate challenging requirements for improved readiness and reduce the lifecycle operation and sustainment costs of current and future tactical systems," Ferguson said.

Published September 2019

Rate this article

View our terms of use and privacy policy